A concrete batch plant is a machine that mixes the various ingredients that are used to make concrete. The elements include water, sand, cement, and aggregates among other ingredients. A concrete pump, on the other hand, is an essential component of the concrete batch plant that is used to transfer concrete from a hopper to the point of use. The concrete pump reduces the amount of time required to take concrete from the hopper as it discharges more concrete per unit time compared to cranes and conveyor belts.

Main Types of Concrete Batch Plants

There are two main types of concrete batch plants:

- The dry mix batch plant(plantas mezcladoras de concreto)

- The wet mix batch plant

The Dry Mix Plant

The dry mix plant is a concrete plant that mixes the ingredients of concrete such as sand and cement without adding water to the mixture. Not adding water to the mixture ensures that the materials are evenly mixed before water is introduced to the mixture. This type of plant is suitable for use when the concrete is to be transported over a long distance a requires a large floor area to facilitate the mixing process.

The Wet Mix Plant

The wet mix plant is a concrete plant that adds water to the dry concrete materials. The wet mix plant is the most common concrete mixing plant that is mostly used on site. Water is added to the cement and sand, and the mixture is stirred together to mix. Water is usually added after the materials have mixed uniformly to ease the process of stirring. The wet mixture is then taken to the sites of use using concrete pumps, conveyor belts or cranes.

Essential Components of Concrete Batch Plants

Commercial concrete batch plants are composed of the following five main components:

- Mixers- The mixer is the main component of the concrete batch plant and is responsible for combining the ingredients of concrete. The mixer is composed of a stirring mechanism that enhances the process of mixing.

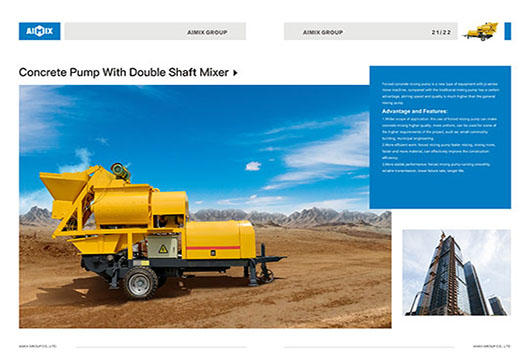

- Concrete Conveying Systems- These systems are composed of concrete pumps( compuesto de bombas de concreto ), cranes and lifts that provide the means of moving the concrete from one point to another. Concrete pumps are used to discharge concrete through pressure to the point of use. On the other hand, cranes and lifts carry the concrete from the point of mixing to the points of use. Concrete pumps are more efficient because they transport concrete at a faster rate than the cranes and lifts.

- Concrete Weighing System- The weighing system is composed of weighing devices that measure the weight of concrete as it leaves the mixer chamber. They ensure that the conveying systems are optimally loaded with concrete to increase the overall efficiency of the batch plant. The weighing devices also prevent the conveying channels from overloading which would compromise their mechanical performance.

- Control Systems- Batch concrete plants have automated, or semi-automated control systems that coordinate and monitor the activities of the plant. Control devices also ensure that the system works with maximum efficiency to minimize wastages and wait time.

- Storage Systems- Storage systems provide platforms that house the concrete before it is used. Dry mix plants require large silos for storing the concrete products while wet mix plants require containers for storing the concrete temporarily as it awaits transport to the points of use.

Features of Batch Concrete Plants

- Require low maintenance cost.

- Ensure consistency of concrete batches.

- Concrete batch plants have high efficiencies.

- Concrete batch plants require a low running cost.

Applications of Batch Concrete Plants

Concrete batch plants are used in construction sites, in mining centers, in petroleum and drilling companies, and airports and road construction industries.

Precautions While Working With Batch Concrete Plants

- The plant should be cleaned and dried after use to prevent rusting of metallic parts.

- Workers working in concrete batch plants should wear safety gears for protection against injuries.

- Qualified operators should monitor all machines at all times.

- Earplugs and noise reduction measures should be put in place to reduce noise pollution.

- Only trained and qualified workers should work with concrete plants.

Choosing the Right Equipment for Your Project

The following factors should be considered when selecting a Concrete batch plant:

- The cost of the plant

The plant should not strain your budget so much.

- The size of the concrete batch plant

Proper plant size should be adopted depending on the size of the project in question.

- The technology employed in the concrete plant

One should decide whether to select automatic, semi-automatic or manual plants depending on one’s preferences and needs.

Main Manufacturers/ Where to Buy Quality Plants

- ELKON Concrete Batching Plant

- Asphalt Batch Plant

- McCrory Batch Plant

- DornerBatch Plant

- SCHWING Stetter Batching Plant

Differences in the Batch Concrete Plants

The main differences in the above concrete batch plants are in the design of the products, the control systems adopted, the size, and the level of technology integrated into the systems.

In conclusion, understanding the details of the concrete batch plants is essential in ensuring that the best decision is made when planning to purchase a concrete plant for a particular construction task.

Best Plant En AIMIX: aimixgrupo.com/