Selecting the appropriate mooring winch for a vessel is a critical decision that impacts the safety, efficiency, and operational effectiveness of maritime operations. Mooring winches are essential for securing a vessel to a dock or buoy and managing the tension of mooring lines. They come in various types and configurations, tailored to different vessel sizes, operating environments, and specific requirements. This passage provides a comprehensive guide on how to select the most suitable mooring winch for a vessel.

Understanding Mooring Winches

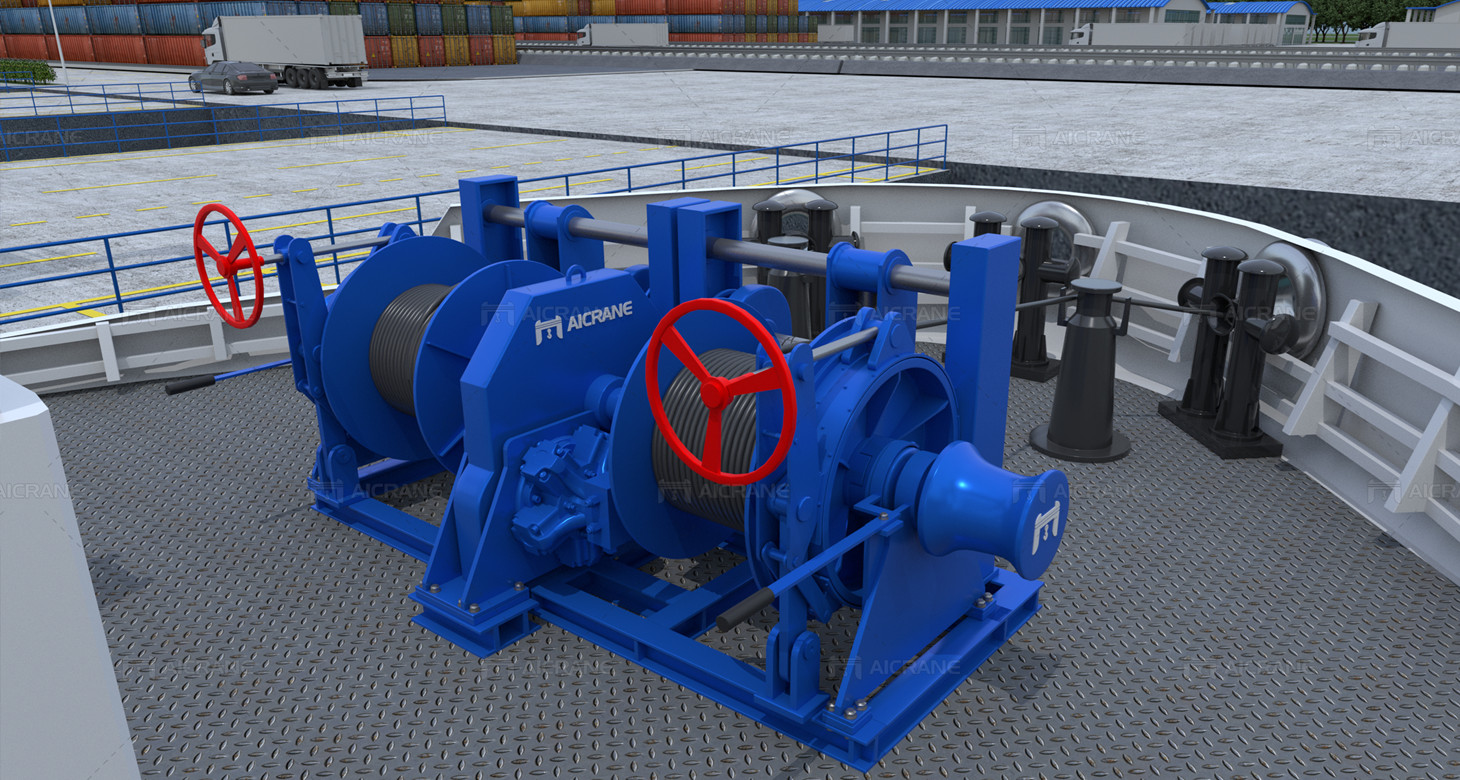

A mooring winch is a mechanical device used on ships to handle and secure mooring lines. These winches consist of a drum, motor, brake, and control system. They can be powered by hydraulic, electric, or pneumatic systems, each offering distinct advantages. There are hydraulic mooring winch, electric mooring winch and pneumatic mooring winch. Key factors to consider include the type of vessel, its size, operating conditions, and specific mooring requirements.

Key Considerations for Selecting a Mooring Winch

Type of Vessel

The type and size of the vessel significantly influence the choice of mooring winch. Different vessels have unique mooring requirements:

Cargo Ships: Typically require mooring heavy duty winches capable of handling large and heavy mooring lines due to their substantial size and weight.

Passenger Ships: Need reliable and smooth-operating winches to ensure the safety and comfort of passengers during docking operations.

Tugboats and Workboats: Require highly maneuverable and responsive winches due to their frequent and varied mooring operations.

Fishing Vessels: Usually demand compact and efficient winches that can operate in harsh marine environments.

Power Source

Mooring winches can be powered by different systems:

Electric Winches: Ideal for vessels with reliable electrical power sources. They are typically quieter and require less maintenance compared to hydraulic systems. However, they may not be suitable for very heavy-duty applications.

Hydraulic Winches: Offer greater power and are suitable for heavy-duty applications. They are robust and can handle higher loads, making them ideal for larger vessels. However, they require more maintenance and are typically more complex.

Pneumatic Winches: Less common but used in specific applications where air power is readily available. They are suitable for smaller vessels or specific operational requirements.

Load Capacity

The winch’s load capacity must match the vessel’s mooring requirements. This includes the breaking strength of the mooring lines and the maximum load the winch will need to handle. Factors to consider:

Breaking Load: The maximum load that the mooring line can handle before breaking. The winch should be capable of handling at least this load.

Working Load Limit (WLL): The maximum load that the winch can safely handle during regular operations. This should be significantly less than the breaking load to ensure safety.

Drum Capacity

The drum capacity of the winch determines the length and diameter of the mooring line that can be stored on the drum. Key considerations include:

Line Length: Ensure the drum can accommodate the full length of the mooring line required for the vessel.

Line Diameter: The drum should be able to handle the diameter of the mooring line without causing excessive wear or damage.

Speed and Control

The speed at which the mooring winch operates can impact docking efficiency and safety. Consider the following:

Haul-In Speed: The speed at which the winch can pull in the mooring line. Faster speeds can reduce docking time but require precise control.

Control Systems: Modern mooring winches often come with advanced control systems, including remote control and automated tension management. These systems can enhance operational efficiency and safety by allowing precise control over the mooring process.

Environmental Conditions

The operating environment significantly affects the choice of mooring winch:

Marine Environment: Winches used in marine environments must be resistant to corrosion and designed to withstand harsh conditions, including saltwater exposure and extreme weather.

Temperature Range: Consider the temperature range in which the winch will operate. Some winches are designed to function in extreme cold or heat, which is crucial for vessels operating in polar regions or tropical climates.

Safety Features

Safety is paramount in mooring operations. Essential safety features to look for in a mooring winch include:

Automatic Brake Systems: Ensure the winch can automatically engage the brake in case of power failure or unexpected load release.

Overload Protection: Prevents the winch from exceeding its maximum load capacity, reducing the risk of equipment failure and accidents.

Emergency Stop: Allows operators to immediately stop the winch in case of an emergency.

Maintenance and Durability

Regular maintenance is crucial for the longevity and reliability of mooring winches. Consider the following:

Ease of Maintenance: Choose winches that are easy to inspect and maintain. Access to critical components should be straightforward.

Durability: The winch should be constructed from high-quality materials that can withstand the operational demands and environmental conditions.

Selecting the suitable mooring winch for a vessel involves careful consideration of various factors, including the type of vessel, power source, load capacity, drum capacity, speed and control, environmental conditions, safety features, and maintenance requirements. Each factor plays a crucial role in ensuring that the winch meets the operational needs and enhances the safety and efficiency of mooring operations.

By thoroughly assessing these aspects, vessel operators can make an informed decision, ensuring that they choose a mooring winch that not only meets their immediate needs but also provides long-term reliability and performance from a reliable winch manufacturer. Investing in the right mooring winch is essential for the smooth and safe operation of any vessel, contributing to overall maritime safety and operational success.