Asphalt mixing plants play a pivotal role in the construction industry, providing the essential materials for building roads, highways, and infrastructure projects. In recent years, advancements in technology have revolutionized asphalt mixing plant operations, significantly enhancing production efficiency, quality control, and environmental sustainability.

Intelligent Process Control Systems:

Modern asphalt mixing plants are equipped with intelligent process control systems that optimize every stage of the production process. These advanced control systems utilize sophisticated algorithms to regulate material feeding, temperature control, and mixing parameters with precision and accuracy. By continuously monitoring and adjusting key variables in real time, intelligent control systems ensure consistent product quality while minimizing waste and energy consumption in an asphalt mixer plant.

Automation and Robotics:

Automation has emerged as a cornerstone of efficiency in asphalt mixing plant operations. Robotic systems and automated machinery streamline material handling, blending, and loading processes, reducing manual labor and human error. Automated systems can perform repetitive tasks with unparalleled speed and accuracy, allowing for higher throughput and productivity levels. Furthermore, robotic technologies enhance workplace safety by minimizing the exposure of workers to hazardous environments.

Advanced Mixing Technologies:

The heart of any asphalt mixing plant lies in its mixing technology. Recent advancements in mixing technologies have led to the development of high-performance mixers capable of achieving superior homogeneity and consistency in asphalt mixtures. Innovations such as counterflow drum mixers, twin-shaft paddle mixers, and continuous mixing systems optimize asphalt blending processes, resulting in uniform mix quality and enhanced workability.

Energy-Efficient Design:

Energy efficiency has become a primary focus in the design and operation of modern asphalt mobile plant. Plant manufacturers are incorporating energy-saving features such as thermal insulation, heat recovery systems, and variable frequency drives to minimize energy consumption and reduce carbon emissions. By harnessing renewable energy sources and adopting sustainable practices, asphalt plants can achieve significant reductions in operating costs and environmental impact.

Real-Time Monitoring and Diagnostics:

Real-time monitoring and diagnostics systems provide plant operators with valuable insights into equipment performance and maintenance needs. Sensors and telemetry devices installed throughout the plant collect data on temperature, pressure, vibration, and other critical parameters. Advanced analytics software processes this data to detect anomalies, predict potential failures, and recommend preventive maintenance actions. Proactive maintenance strategies optimize equipment uptime and reliability, minimizing unplanned downtime and production disruptions.

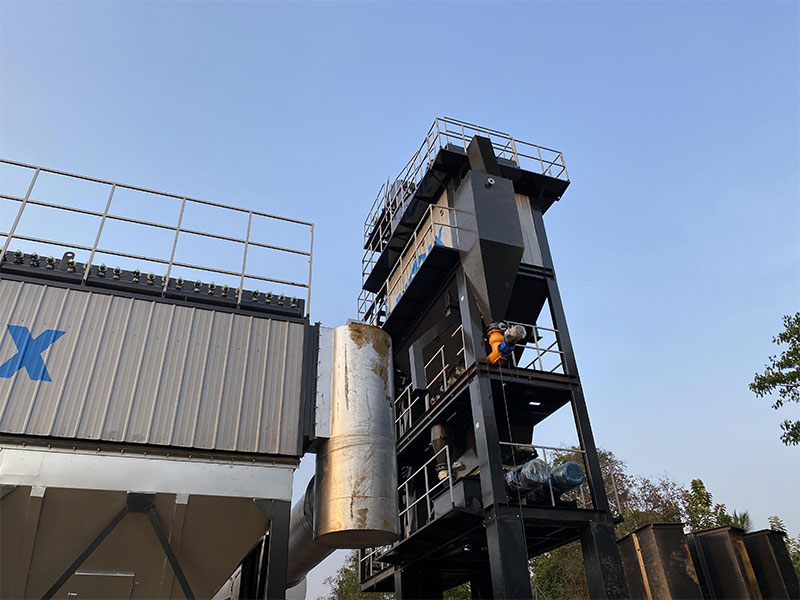

Mobile and Modular Designs:

Mobile and modular asphalt mixing plant designs offer unprecedented flexibility and scalability in deployment. These compact and portable asphalt plants for sale can be easily transported to remote construction sites or relocated as project requirements dictate. Modular construction allows for rapid assembly and disassembly of plant components, facilitating quick setup and commissioning. Mobile and modular designs enable construction companies to adapt to changing market conditions and project demands with minimal lead time and investment.

Environmental Compliance Solutions:

Asphalt mixing plants are subject to stringent environmental regulations aimed at minimizing air and noise pollution, as well as preserving natural resources. To address these challenges, manufacturers are integrating innovative environmental compliance solutions into plant designs. Advanced dust collection systems, noise attenuation measures, and emissions control technologies ensure compliance with regulatory standards while safeguarding the health and well-being of surrounding communities.

Integration of Digital Technologies:

Digital technologies such as cloud computing, Internet of Things (IoT), and artificial intelligence (AI) are transforming asphalt mixing plant operations. Cloud-based platforms enable remote monitoring, data analytics, and performance optimization from anywhere in the world. IoT sensors and AI algorithms enhance predictive maintenance capabilities, optimizing equipment reliability and lifecycle management. Digital integration enhances collaboration, efficiency, and decision-making across the entire value chain.

Conclusion:

The relentless pursuit of innovation and technological advancement has propelled hot mix asphalt plant production efficiency to unprecedented levels. Intelligent process control systems, automation, advanced mixing technologies, energy-efficient design, real-time monitoring, mobile and modular designs, environmental compliance solutions, and digital integration are among the key drivers of this transformation. By embracing these technologies, asphalt mixing plants are poised to meet the evolving needs of the construction industry while advancing sustainability, productivity, and performance standards.